The best Side of DTF Transfers

The best Side of DTF Transfers

Blog Article

The transfer approach is completed working with warmth and stress. after the PET film is positioned on to the material, the applied heat and strain allow the ink to go through the PET film and on to the material.

The chart and numbers may be adjusted dependant on much more specific demands, such as specific style and design and dimensions requirements.

Pro idea: When your garment measurements range each of the way from youth to Grownup 3XL, you might want to think about using two distinct print dimensions so your design and style will look proportional. A Centre chest can appear huge on more little shirts and smaller on more significant ones.

You need a heat press to perform DTF printing. The heat push is used to transfer the types on the check here PET movies on to the desired floor for printing. Heat and force facilitate the transfer course of action.

since we know very well what DTF heat transfers are, let’s discover the benefits they provide for your enterprise.

Pre-manufactured and Ready to implement: compared with conventional printing techniques, there’s no need to create your very own designs. DTF transfers are pre-printed and are available all set to press, conserving effort and time.

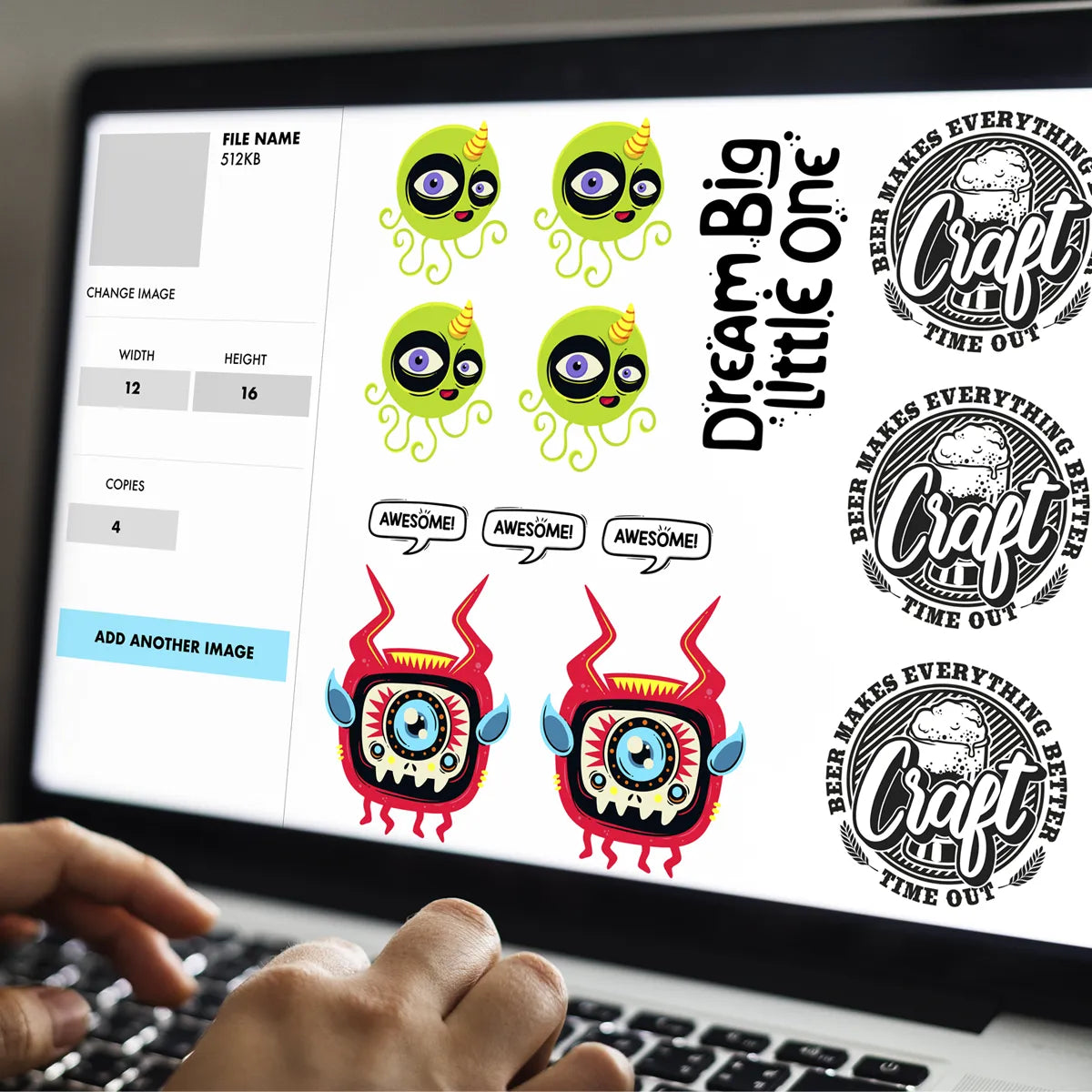

Be happy to utilize this Software to be sure your style and design aligns correctly using your vision. When choosing a transfer size, it is necessary that the transfer matches the scale of the layout or is much larger for ideal success.

Yet another significant advantage of DTF warmth transfers is the ability to print whole-color layouts. regular display printing is limited to a particular variety of shades, which could ensure it is hard to attain sophisticated or thorough designs.

Print place - This refers to the spot about the garment or maybe the class of print (remaining upper body print, full again print). Placement and print area can vary throughout the print place.

Ease of Use: DTF able to push solutions simplify the applying procedure, which makes it obtainable for novices.

Anchor position - The purpose on the design that should be centered as an alternative to the midpoint. This is beneficial for figuring out on models that are not By natural means symmetrical.

3. making use of the Adhesive: A powder adhesive is placed on the wet ink right after printing. This adhesive makes it possible for the design to bond with the fabric when heat pressed.

This may help you create a standing for high-quality and trustworthiness, which can cause additional repeat company and referrals.

Heat push: you'll need a warmth push to use your DTF transfer to your garment. ensure your warmth push is compatible with DTF transfers and has the appropriate temperature and tension configurations.

Report this page